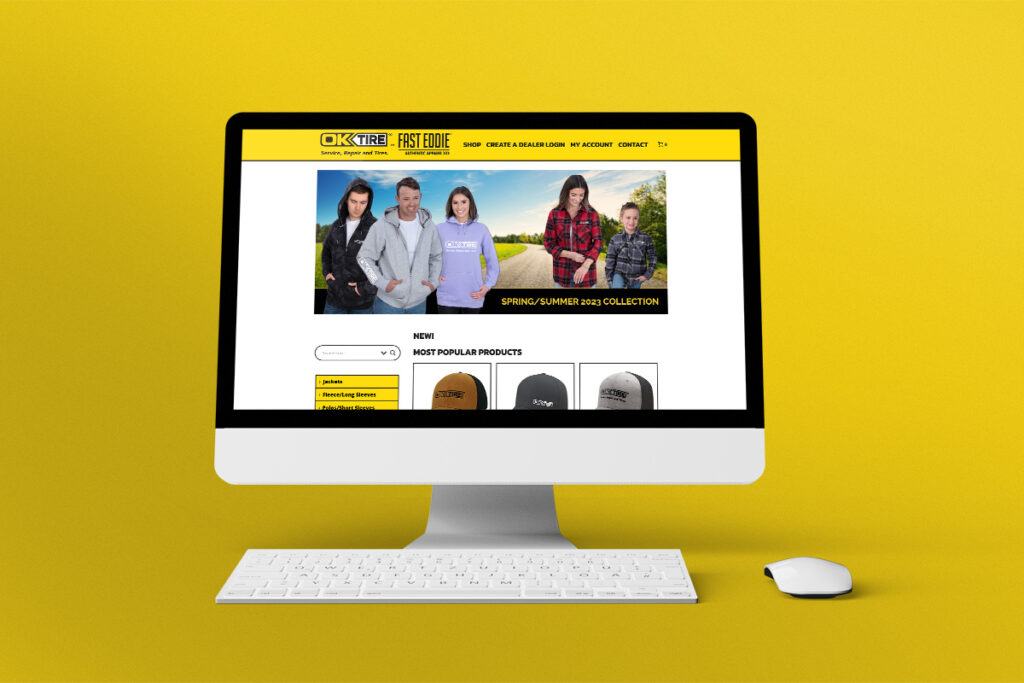

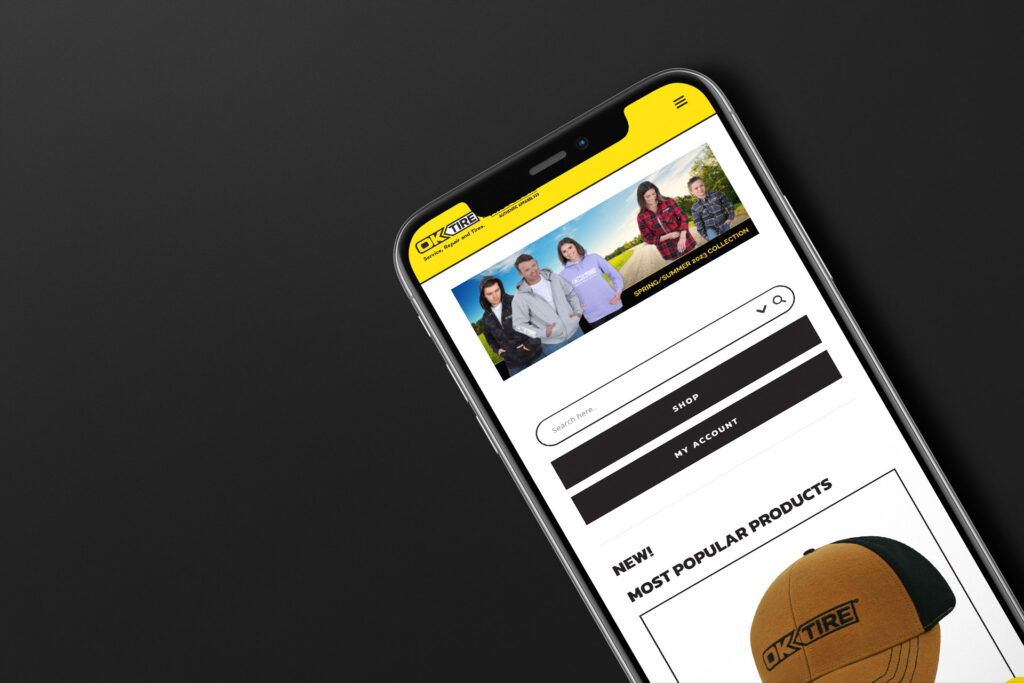

OK Tire Case Study

Finding the right product for your company and staff is never an easy task. Some people like it one way and some people another, it can sometimes be difficult to find that balance. Here at Fast Eddie we want to alleviate the burden and help find the solution. Our core focus is to offer quality, fashionable products that everyone will want to wear.

With our own in-house art department and product development team we look at emerging trends in the marketplace and analyze what works well in each industry to ensure we are offering the best products to our clients. While all of our hard work researching fashion and trends certainly help, over the years we have found that the best way to serve our clients better is by simply asking them what they want.

Here’s how we helped the OK Tire brand grow its offering and how we became the official licence holders and suppliers for them:

1

Our first connection – The story starts at a trade show we attended. The owner of an OK Tire store walked past our booth, saw some shirts we had designed and manufactured and asked if we could create some for them. From there word spread and before we knew it we were suppliers to several stores; this expanded quickly and today we are the official suppliers to OK Tire.

2

Understanding the Brand – When we started discussing the line up with OK Tire our team researched the company, what they offer, their history, their story and what their core values are. From there they were able to understand more about who they are, what makes them stand out from other companies and what makes OK Tire authentically OK Tire.

3

Going out in the field – We are a little more traditional when it comes to connecting with the end consumer. We got out of the office and visited a number of the stores to meet with the staff, find out what they like and to ask what they are looking for in the apparel program.

4

Program development – Based on the store feedback, our research of the fashion market and knowledge, we set about creating a brand new program. We designed goods that were practical within their field, comfortable, included their colours, items that were for everyday wear and durable.

5

Manufacturing – Once we submitted our designs for review and approval we set about manufacturing them. Here our product development team analysed sizes, measurements, material, correct colour swatches and so much more. Each individual design was brought to life and once they were perfectly in line with our vision, the machines were turned on and production started.

6

End result – While product was being made, we set about creating a catalogue for all stores to shop from. We had samples of each item and went for photo shoots to showcase the item better than a standard hang on the rack picture. Our art department worked tirelessly creating a catalogue that showcased the product and highlighted the features of it. Once complete, we had them shipped out to all stores across Canada. When our first order came in, a whole new story began.